Inspection & Expediting Services

Inspecting Services

SHOP INSPECTIONS

Shop inspections are performed to supervise and control production processes, to verify product quality or to accept ready products.

The service aims to control, at the facility of the manufacturer or sub-contractor, the quality of workmanship and the conformity of the manufactured equipment with the purchase specifications, the applicable drawings, codes and standards and other relevant contractual documents. The level of involvement can be specified by the client, and may include stage inspections, witness testing or final inspection.

Shop inspections have a dual benefit for the project, as they have both a corrective and a preventive

component. When non-conformities are detected during shop inspection, they can be corrected. Also,

the knowledge that shop inspections on behalf of the client are taking place or surprise inspections

can be expected at any time will stimulate the manufacturer to produce faultless products

EQUIPMENT INSPECTIONS

All types of mechanical, electrical and electron equipment are inspected to verify compliance to specified standard & Projects requirements. According to the size and complexity of the equipment, one inspection visit, or several visits shall be made; in the latter case, inspection could start with a pre-production meeting followed by identification and inspection of all raw materials, inspections at all prescribed hold-point stages, witnessing all tests, verification of all certificates and as specified by Client issuances for final inspection release for shipment

MILLING INSPECTIONS

As regard to inspection and certification of plates, line pipes, castings, tubing’s, etc., our specialist inspectors have knowledge of forming, welding, non-destructive testing, threading, coating, stocking, loading etc. For large orders, a team of inspectors is placed in the mill in all shifts and all stages of manufacture and test are controlled. Detailed reports are issued on shift, weekly and completion basis; reports are either manual or computerized. The latter is a distinct aid in controlling the certification and helps with material traceability.

Pre-shipment Inspections

Pre-shipment inspection is offered to exporters and importers and comprises a detailed inspection of equipment or materials after manufacture, but prior to shipment. The scope includes Quality, Packing & Marking and Supervision of Loading. A Certificate of Inspection can be provided.

Expediting Services

EXPEDITING

GE-QS offers a broad range of Supply Chain related services to assist engineers, contractors and constructors. As part of the Supply Chain, expediting is performed to supervise delivery timing and schedules.

The purpose of the expediting service is to ensure the delivery of purchased goods to a pre- determined and promised delivery schedule or critical path network. It is the task of the expeditor to detect and analyses the areas, which might cause or entail delays. The expeditor must obtain or reaffirm delivery promises from suppliers, must fully investigate all aspects of the suppliers scheduling which are evidence of the practicality of achieving such promises and must physically check progress of all functions of the suppliers’ operations being engineering, procurement, production and shipping departments.

The outcome of the service is to suggest constructive solutions in order to meet the schedule, inform the client of the real situation existing and of all decisions taken to meet the pre- determined schedule. GE-QS can perform expediting services to a sequential group of activities forming a chain within the network plan, a selected number of activities or indeed the total project activities.

VENDOR ASSESSMENT

Assessments of the capabilities and capacities of proposed suppliers are made at the pre-award stage in order to ensure that suppliers can handle specific purchase orders in terms of quality and delivery.

VENDOR SURVILLIENCE

The service aims to control, at the premises of the manufacturer or sub-contractor, the quality of workmanship and the conformity of the manufactured equipment with the purchase specifications, the applicable drawings, codes and standards and other relevant contractual documents. The level of involvement can be specified by the client and may include stage inspections, witness testing or final inspection. The Inspection includes:

Pre-production inspection of raw materials

- In-work inspection to check quality levels are being maintained during production

- General QC checks prior to transit to ensure the consignment meets with specification and / or conforms with letters of credit

- Inspection of delivered consignments at buyer’s premises to verify goods conform to pre- sealed samples or pre-defined quality levels.

- Third party verification of delivered consignments

- Inspection to sort any ‘good’ from ‘bad’

QUALITY ASSURANCE AUDITS

QA audits are made of suppliers by experienced and trained assessors both before contract award and during manufacture. Such audits ensure compliance with required QA procedures and ensure that materials and equipment are produced to the required quality level without time rejections and rectifications.

GE-QS offers a truly independent service and can handle single purchase orders or complete projects.

PROJECT COORDINATION

Project management services are taking work out of the hands of our customers. GE-QS co- ordinates the different steps in review, verification, inspection, testing and approval. And moreover, we help you run the project. Project management involves:

- Carry out prequalification of suppliers and sub-contractors.

- Prepare Inspection Plans.

- Review suppliers QA / QC procedures.

- Carry out inspection and expediting during manufacture.

- Carry out witness tests.

- Control of quantities, packing and marking.

- Control of loading.

- Supervision and inspection on site during construction.

- Supply of technical specialists of all disciplines.

- Non-Destructive Testing.

ENGINEERING SECONDMENT SERVICES

Secondments Services of AWS/CSWIP Welding Inspectors, BGAS Painting Inspectors, API 510 & 570 Inspectors & QC Engineers for OIL & GAS Projects. GE-QS provide qualified Inspectors and Engineers for various projects. The level of ATS involvement will be identified in an Inspection and Test Plan and depends on the equipment and application. It may include stage inspections, witness testing or final inspection in accordance with the client’s requirements.

WPS/PQR Preparation and Welder Qualifications

GE-QS provide Welding procedure specifications (WPS) & Procedure qualification Records (PQR) preparations & Welder’s certification as per ASME and AWS standards.

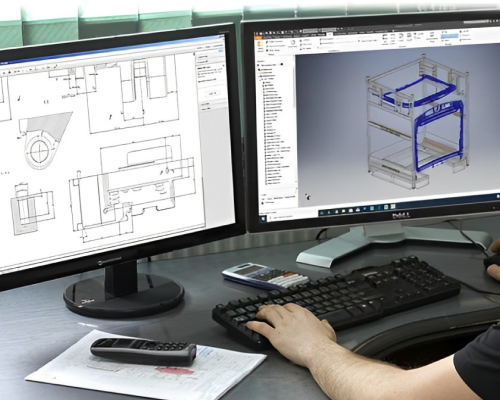

DESIGN AND ENGINEERING SERVICES

GE-QS provides the complete range of services needed to Conceptualize, Design, and Engineering of projects to meet the specific requirements of its clients. GP-QS offers services to industries ranging from Oil, Gas, Offshore, Chemicals, Power, Infrastructure and Communication. Its association with clients extends beyond the commissioning of their plants through monitoring operation and performance.

The Engineering Services offered by GE-QS Includes:

- Design Engineering & Consultancy Services

- Design Appraisal , Verification and Approval

- Structural Engineering

- Mechanical Engineering

- Pressure vessels, Boilers and Piping

- Specialist materials Services

- Advanced Control & Optimization

- Other Services

DESIGN AND CONSULTANCY SERVICES

GE-QS provides cost effective engineering solutions to Oil, Gas, Power and Chemical Industries. Highly professional Civil, Structural, Mechanical, and Electrical & Instrumentation Engineers & Designers strive to deliver engineering drawing and documents. The engineering deliverables are of high quality, cost effective & best in industry standards. Specialized services are provided in the field of static & dynamic analysis of equipment, structures and trouble shooting.

DESIGN APPRAISAL

GE-QS extends its support in design appraisal by reviewing the design and drawings to confirm its compliance to the codes, regulations and client requirements. This avoids the critical mistakes well in advance before start of procurement of materials fabrication.

STRUCTURAL ENGINEERING

GE-QS ensures high quality & cost-effective services to the customer. GE-QS offers expertise in both onshore and offshore industry. Structural design are carried out by dedicated & experienced personnel using globally accepted software’s. Design services cover most of the international codes & standards.

Structural division services include but not limited to the engineering of:

- Process & Technical Structures.

- Pipe racks & Pipe Bridges.

- Industrial Building & Foundations.

- Topsides facilities for offshore platforms.

- Review of Structural designs & drawings.

- Technical services / assistance.

MECHANICAL ENGINEERING

GE-QS delivers state of art engineering products to our valued customers. We are your best choice for Thermal and Mechanical design of pressure equipment such as pressure vessel, piping, Heat Exchangers, Columns, Tanks, etc. Our services cover design in accordance with ASME sec VIII Div. 1, ASME Sec VIII Div.2, PD 5500, PED requirements (CE marking), B31.3, etc. Our Cost effective thermal and mechanical design of heat transfer equipment and piping is carried out with globally accepted software’s.

OTHER SERVICES

GE-QS also offers

- Project Management

- Planning & Scheduling.

- Procurement

- Construction Quality Management

- Energy Conservation Audit / Consultancy

- Plant Operation & Safety Audit / Consultancy

PIPELINE ENGINEERING AND INSPECTION

GE-QS provides Pipeline Engineering and Inspection Services both for Onshore and Offshore Pipelines, these include

OFFSHORE PIPELINE

- Inspection and Certification of Materials.

- Approval of Welding Procedures and Mechanical Testing

- Approval of Testing and NDE Procedures and Quality Plan.

- Supervision of Pipelay Operations.

- Welding Inspection.

- Inspection of Hydrostatic Testing, Drying.

- Pipeline Commissioning.

ONSHORE PIPELINES

Provide the services detailed above where relevant and in addition undertake the following for Onshore Projects:

- Pipeline right of way Land Management and Reinstatement.

- Review of Pipeline as built drawings.

- Corrosion Consultancy

- Cathodic Protection.

NON-DESTRUCTIVE EXAMINATION AND HEAT TREATMENT

GE-QS provides Pipeline Engineering and Inspection Services both for Onshore and Offshore Pipelines, these include:

- Ultrasonic Examination

- Radiography by Gamma Ray (sub-contractor) Magnetic particle Examination

- Dye penetrant Examination Vacuum Test

- Holiday Test

- Positive Material Identification (PMI)

- Port Weld Heat Treatment (PWHT)

- NDE Technology are constantly trained & guided by in house Level III examiners, Metallurgists & ASME inspectors for code knowledge update.

Ensure quality and compliance. Contact us for inspection services tailored to your needs.